The Fremantle Smelting Works

Copied from "Twentieth century impressions of Western Australia",

published 1901, Battye Library.

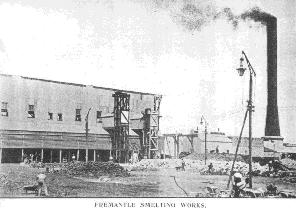

The business carried on by the Fremantle Smelting Works Limited at

South Fremantle is quite one of the important industries of the State, and

is expanding rapidly with the development of the vast mineral resources

of Western Australia. Mr. J.W. Sutherland, the general manager of

the Golden Horseshoe Estates Company Ltd., of Kalgoorlie, is also the

general manager and attorney of this company.

The business carried on by the Fremantle Smelting Works Limited at

South Fremantle is quite one of the important industries of the State, and

is expanding rapidly with the development of the vast mineral resources

of Western Australia. Mr. J.W. Sutherland, the general manager of

the Golden Horseshoe Estates Company Ltd., of Kalgoorlie, is also the

general manager and attorney of this company.

The supplies of gold and other ores are drawn from all parts of the State;

but the main source is the Kalgoorlie belt, large quantities of high-grade

sulphide ore from this field being treated regularly.

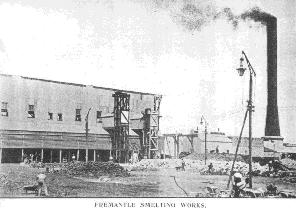

It is scarcely possible to imagine a more ideal spot for a smelting works.

It is well removed from the populous parts of the port, although connected

with the main railway system of the State by a branch line, and stands on

an elevated position overlooking the Indian Ocean.

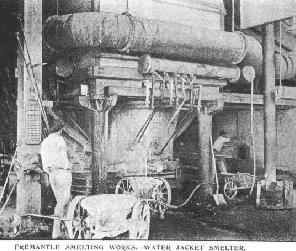

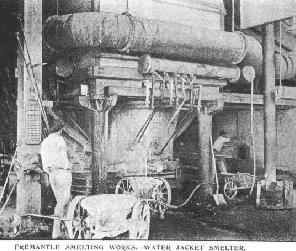

The smelting furnaces are three in number, each 212 inches by 52 inches,

water-jacketed and provided with the necessary steam engines, blowers, hydraulic

plant, electric light, etc. Five roasting furnaces of the reverberatory

type are used for roasting the lead concentrates and the auriferous

pyritic concentrates, the fuel used being Collie coal and wood. Four

Baker-Green rotary blowers are kept in blast by a 200 horse-power horizontal

high and low pressure engine by Martin and Co., of Gawler, and steam for

this is supplied by three Lancashire boilers, the chief fuel being Collie

coal. One thousand tons of this coal are used every month, the

Fremantle Smelting Works being thus, next to the Railway Department, the

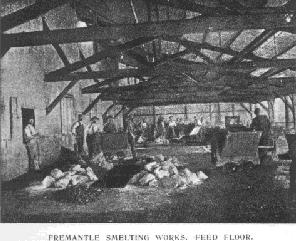

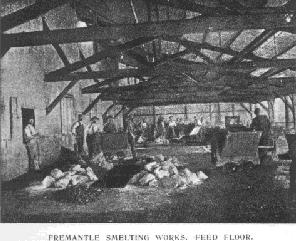

largest consumers of coal in the State.  The Otis elevators, of which there are seven, and the arrangements

in connection with the electric lighting, the supply of salt water for the

jackets of the furnaces, and fresh water, etc., all call for special machinery.

A briquetting plant for the purpose of treating very fine gold ore

and flue dust, is in operation, and a gas producer for the purpose of the

economic utilisation of the waste Collie coal on the roasting furnaces is

also in use.

The Otis elevators, of which there are seven, and the arrangements

in connection with the electric lighting, the supply of salt water for the

jackets of the furnaces, and fresh water, etc., all call for special machinery.

A briquetting plant for the purpose of treating very fine gold ore

and flue dust, is in operation, and a gas producer for the purpose of the

economic utilisation of the waste Collie coal on the roasting furnaces is

also in use.

In one way and another the works give employment directly to some 400 hands,

and, indirectly to a vast number more. In addition to the 1,000 tons

of coal, there is a monthly consumption of 2,300 tons of ironstone flux

and 3,000 tons of limestone flux, also 1,200 tons of English and Australian

coke.

Regular shipments are made of the bullion produced, to London per mail

steamers each week.

Export statistics in tons for Lead, copied from the Pocket

WA Yearbook for 1920, Battye Library.

Pig Lead 1917 4,661

'' '' 1918 5,489

'' '' 1919 1,780

'' '' 1920 1,930

By 1920 there had been 18,080 tons Pig Lead exported from Western Australia,

since records began.

See the maps page for image of 1908 Metro Sewerage

plan showing details of Fremantle Smelter Works site. Note slag dumps

so near sea in 1908 that it is probable slag was eroded by the sea in

the 12 years of operation after that. Although most of the slag was

eventually spread on Perth roads, the furnace and casting environs at the

base of the three stacks have never been de-commissioned and could be

expected to rank with the most metal polluted ground in the Perth region.

Back to home page

The business carried on by the Fremantle Smelting Works Limited at

South Fremantle is quite one of the important industries of the State, and

is expanding rapidly with the development of the vast mineral resources

of Western Australia. Mr. J.W. Sutherland, the general manager of

the Golden Horseshoe Estates Company Ltd., of Kalgoorlie, is also the

general manager and attorney of this company.

The business carried on by the Fremantle Smelting Works Limited at

South Fremantle is quite one of the important industries of the State, and

is expanding rapidly with the development of the vast mineral resources

of Western Australia. Mr. J.W. Sutherland, the general manager of

the Golden Horseshoe Estates Company Ltd., of Kalgoorlie, is also the

general manager and attorney of this company.

The Otis elevators, of which there are seven, and the arrangements

in connection with the electric lighting, the supply of salt water for the

jackets of the furnaces, and fresh water, etc., all call for special machinery.

A briquetting plant for the purpose of treating very fine gold ore

and flue dust, is in operation, and a gas producer for the purpose of the

economic utilisation of the waste Collie coal on the roasting furnaces is

also in use.

The Otis elevators, of which there are seven, and the arrangements

in connection with the electric lighting, the supply of salt water for the

jackets of the furnaces, and fresh water, etc., all call for special machinery.

A briquetting plant for the purpose of treating very fine gold ore

and flue dust, is in operation, and a gas producer for the purpose of the

economic utilisation of the waste Collie coal on the roasting furnaces is

also in use.